Model 390 High-Speed Ream Wrapper

Product Description

- Wraps all standard U.S. and metric ream sizes

- Up to 150 reams per minute (A4/Letter size)

- High-quality wrapping including precise print registration

- Automated operation

- Servo driven machine for reliable performance & reduced maintenance

- Compact footprint (electrical enclosure mounted in machine) & easy accessible design

- Options include polypropylene capability, external girth glue sealing & Turret roll stand

- Integrated paper mills & large converters of Standard U.S. and metric paper sizes

Product Features

The Model 390 ream wrapper is ideal for integration with high-volume cut-size sheeting operations where exceptional quality is a must. The machine is designed for high-speed wrapping of standard U.S. and metric ream sizes and is set-up to run registered wrapping material ranging from standard Kraft, poly coated, or polypropylene wrapping paper.

High Output

Precise Registration

Compact Machine

Simple Operation

| Metric | Imperial | |

|---|---|---|

| Package size range | 275 - 300 mm (length) 200 - 220 mm (width) 20 - 65 mm (height) | 10.8 in - 11.8 in (length) 7.8 in - 8.6 in (width) 0.8 in - 2.6 in (height) |

| Roll stand | up to 1270 mm diameter roll | up to 50 in diameter roll |

| Production Speed | up to 150 reams per minute (A4/Letter size) | |

| Wrapping material | Standard Kraft paper, inside or outside poly-coated Kraft paper, polypropylene film (BOPP) | |

Model 390 High-Speed Ream Wrapper

Compare With

Ideal for handling pre-printed wrap with precise registration

The WillPemcoBielomatik Model 390 ream wrapper is designed for high-speed wrapping of standard U.S. and metric ream sizes. It is set up to run pre-printed wrap with precise registration – end-to-end and side-to-side. Advanced engineering features provide automated operation, minimal maintenance and fast changeovers.

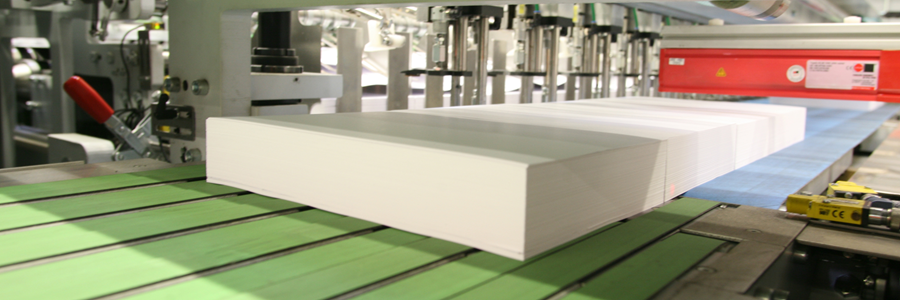

High output for large volume production

An impressive output of up to 150 A4 or Letter size reams per minute makes this wrapper a key component of any high-volume cut-size sheeting and packaging line. Wrap materials include standard Kraft paper, inside or outside polycoated Kraft paper and polypropylene film (BOPP).

Precise and efficient ream wrapping

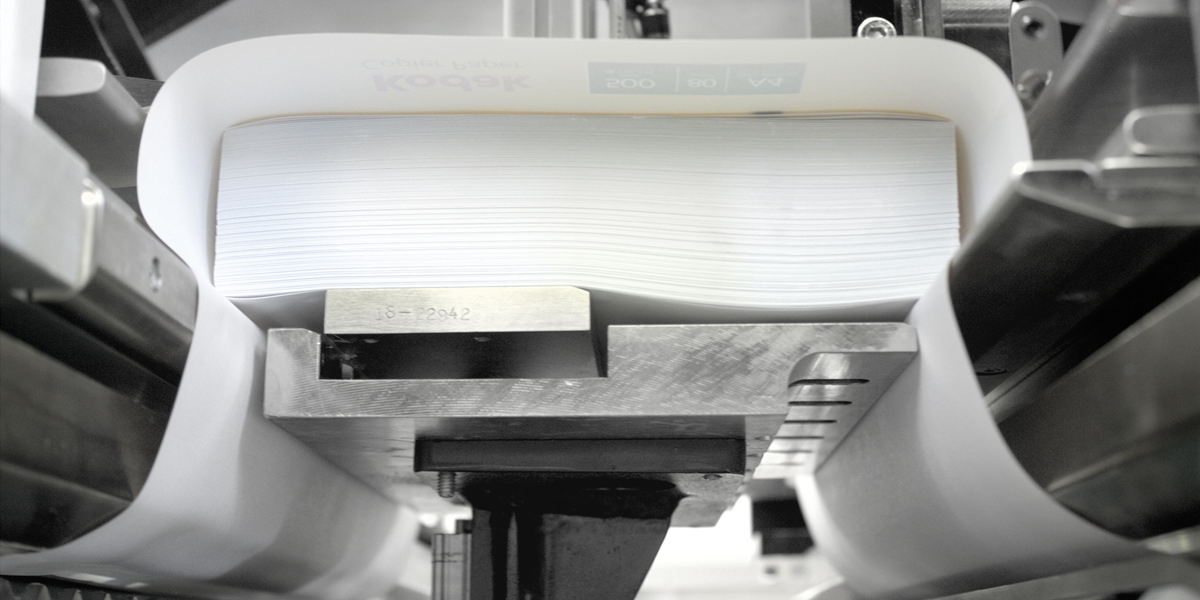

Reams are fed into the wrapper via a servo-driven, smart and flightless conveyor that also accepts and corrects for variance in ream spacing. During wrapping, a fixed ream stop maintains the consistent paper position and a sheet holder ensures precise wrap placement. The result: accurate, reliable wrapping quality for each ream.

Operator interface with touchscreen

A touchscreen simplifies machine operation and diagnostics. Its display screen diagrams the machine layout to aid operator control and guides the operators with a registration instruction sequence when running registered wrap. Programmable recipes for size change are available for shorten changeover times.

Servo driven machine for reliable performance

System solutions for cut-size ream wrapper Model 390

- WillPemcoBielomatik cut-size sheeters (e.g. SLK 490 (7-10 pockets) and SLK 470 (11-16 pockets)

- Further WillPemcoBielomatik packaging machines like

- Ream labeler

- Ream inspection/rejection

- Ream stacker / accumulator

- Case packer/lidder

- Case labeler

- Case inspection/rejection

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)