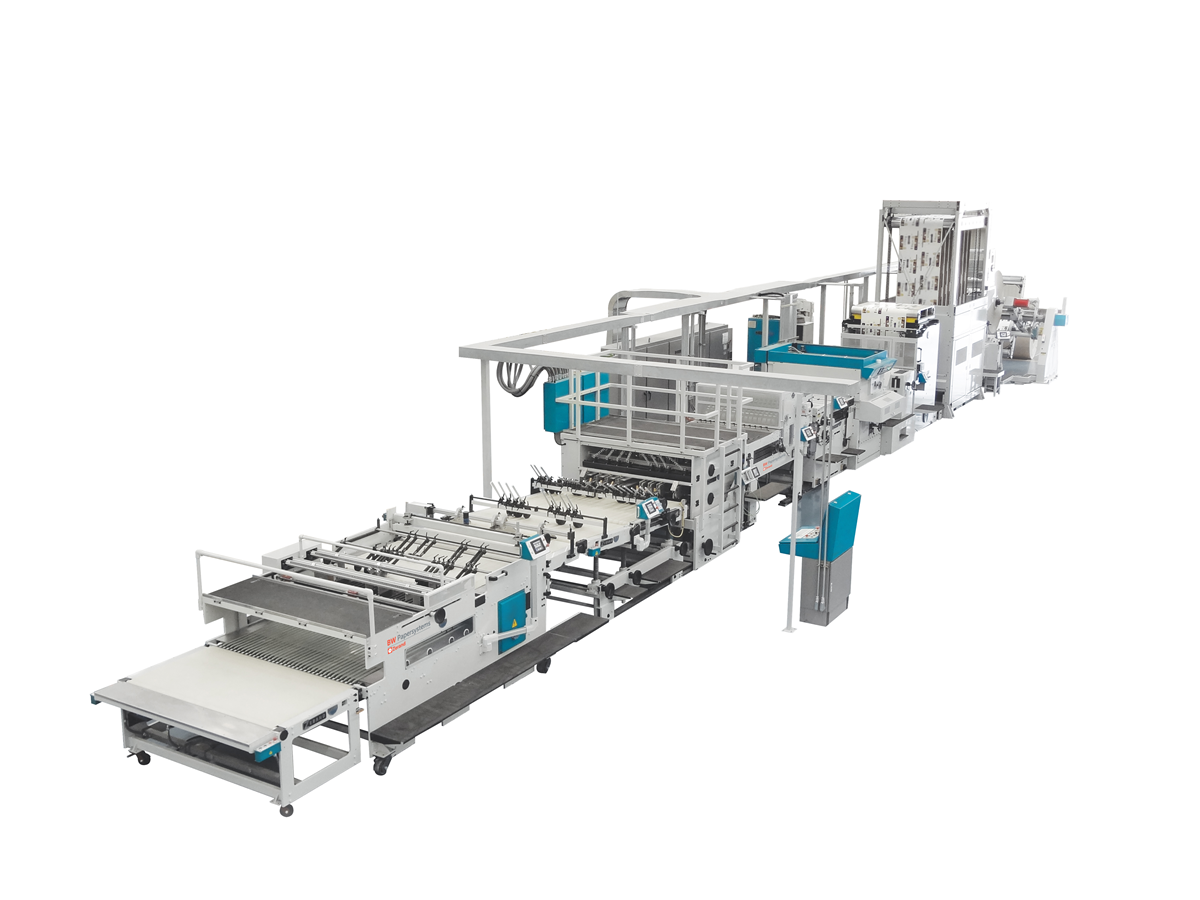

ELS (Electric Line Shaft) Waste Stripper

Product Description

Once a carton has been precision-cut, the ELS Waste Strippers efficiently removes the waste. Accurate waste removal without unnecessary, complex and time-consuming operations is ensured by belt transport of cartons through the strippers.

The stripper uses three servo-motors to drive the reciprocating nip cam, nip rolls, transport belt section and pin cylinders separately, while timed to the platen die cutter position. The reciprocating nip and pin cylinder may be independently adjusted while the platen die cutter is running, or while it is stationary.

Because displays are provided for readouts of the pin cylinder and nip timing relative to the platen die cutter, the user can reduce make-ready time and carton waste. To speed up the stripper changeover from one job to another, the pin cylinder and anvil roll chucking mechanisms use pneumatic cylinders to compress the chucking springs. Once the pin cylinders and anvil roll are in place, a flip of the selector switch will lock them there.

The strippers’ user-friendly, motorized adjustments deliver easy, precise performance. Predrilling the removable pin cylinder off-line allows you to reduce changeover time.

Product Features

Efficiently removes waste

Three servo-motors

Fast Changeover

User-friendly

ELS (Electric Line Shaft) Waste Stripper

Compare With

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)